Single Phase Induction Motor

Types, Working principle and Diagram .

1- Single Phase Induction Motor:

Single phase induction motor converts electrical energy into mechanical energy which is run by single phase power supply and gernerates electromotive force for moving the rotor. Single phase induction motor is used in world as commonly. it is used in single phase applications such like as fan, cooler, AC, refrigerator, water pump, washing machine and industries as small uses.

2- Types of single phase induction motor:

Split Phase induction motor

Split phase induction motor in commonly used in domestic and industrial. It has two no’s winding; one is main winding and 2nd is starting winding or auxiliary winding. Auxiliary winding is connected with capacitor. Both winding is installed in 90° angle with each other.

It is used only constant speed and different type load. It is available in market as 1/3 HP to 5 HP.

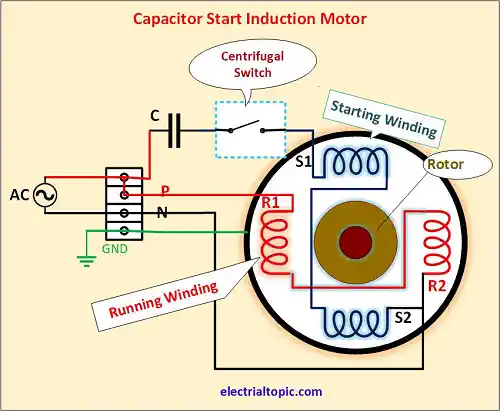

Capacitor start induction motor

For motor starting torque increasing, the capacitor is connected in series with starting winding and

centrifugal switch.

There are two winding are used in motor one is main and second is starting. Both are connected with parallel

with

supply.

When motor starts and get 75% speed then same time centrifugal switch is disconnected from power

supply.

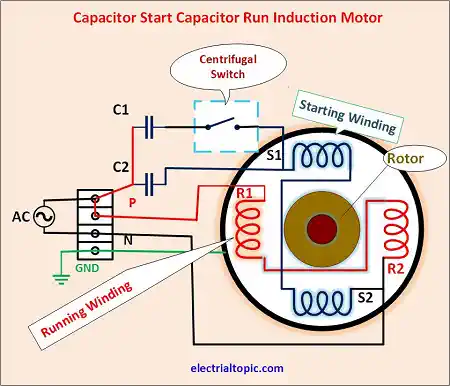

Capacitor start capacitor run induction motor.

Capacitor start and capacitor run induction motor is used for high starting torque and smooth running with power factor maintaining. For motor starting torque increasing, the capacitor is connected in series with centrifugal switch. Another capacitor is connected in series with starting winding.

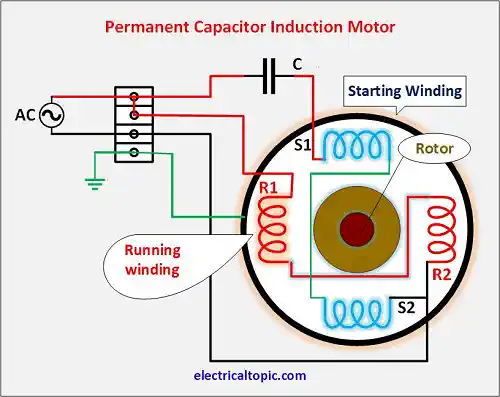

Permanent capacitor induction motor

Permanent capacitor induction motor is used in domestic use, household uses like a ceiling fan, exhaust fan, ac fan, blower etc.

A capacitor is connected with starting winding in series permanently. Starting winding phase is converted by capacitor in another phase. so, this type process is called split phase and motor is called split phase induction motor. both winding works as each other as two phases with 90° angle.

Shaded type induction motor.

3- Single Phase Induction Motor wiring diagram:

1- Split Phase Induction Motor wiring diagram.

2- Capacitor Start Induction Motor wiring diagram.

3- Capacitor Start Capacitor Run Induction Motor wiring diagram.

4- Permanent Capacitor Induction Motor wiring diagram.

4- Single Phase Induction Motor working Principle:

1- Split Phase Induction Motor working Principle:

Main and starting winding is connected with parallel. Main is connected to the supply directly and firstly starting or auxiliary is connected to the centrifugal switch in series after that is connected with supply in parallel.

When start the motor and get 75% to 80% speed, same time the centrifugal switch is disconnected from power supply after that motor runs on main winding separately.

2- Capacitor start induction motor Working Principle:

Some time we need more torque in starting then capacitor start induction motors are used. A powerful capacitor can be used in it. Two winding one is main and one is starting winding, one centrifugal switch and capacitor which is used in series with starting winding.

When the motor is started then it gets speed above 75% or set value, same time centrifugal switch is disconnected from power supply. The motor moves frequently on main winding.

3- Capacitor start capacitor run induction motor working principle:

Two capacitors are used, one is connected in series with centrifugal switch and other is connected with starting winding as series. Both winding is connected parallel with power supply.

When motor is started and it gets above 75% speed then same time starting torque capacitor is disconnected by centrifugal switch after that already connect low-capacity capacitor in series with starting winding works continue as main winding. Motor moves on main and starting winding

4- Permanent capacitor induction motor Working Principle:

This type motor is known as split phase induction motor. its works on two phase winding one is main or running winding and second is starting winding or auxiliary winding.

Main winding is connected with direct power source but starting winding is connected to power source through capacitor in series connection. The amplitude of starting winding has been changed by capacitor extra charging so it behaves as another phase.

Due to difference of magnetic flux to each other like as two phase the motor starts move.