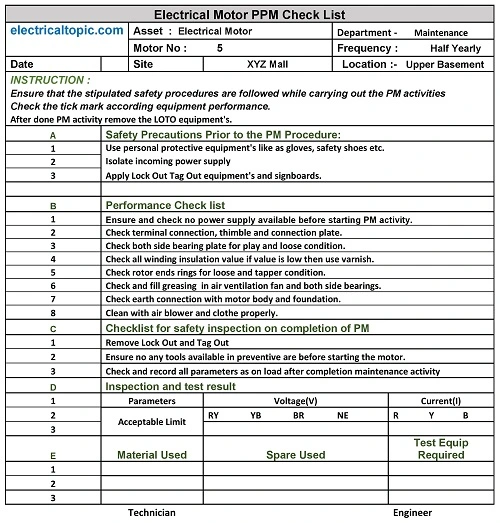

Electrical Motor PPM checklist

Description, Types and maintenance checkpoints.

1- Electrical motor maintenance checklist:

Electrical motor is a costly electrical device which is used for electrical power into mechanical power.

Preventive

maintenance is a important activity for keeping good health of electrical motor.

Many type

maintenance activity is carried out as monthly, quarterly, half yearly and yearly.

These all activities

is

carried out according maintenance checklist which is written step by step maintenance process.

2-Format or template of electrical panel PPM checklist:

3 - Types of electrical motor maintenance checklist:

- Monthly

- Quarterly

- Half Yearly

- Annually or Yearly

4-Details of safety guideline for electrical motor PPM activity:

During PPM activity we should follow safety guideline for stopping any misshaping. Safety related some points below mentioned.

- Isolate electrical energy source from motor starter panel.

- Use lock out and tag out on the electrical starter panel.

- Use insulated tools.

- Use personal protective equipment as safety shoes, helmet etc.

- After completion activity remove tools and tackles.

- After completion remove safety lock and signboard or tag.

5-Electrical motor maintenance activity checkpoints:

- Ensure and check no power supply before starting PM activity.

- Check terminal connection, thimble and connection plate.

- Check both side bearing for any play or loose condition.

- Check all winding insulation value if value is low then use insulation varnish.

- Check rotor ends rings loose or tapper condition.

- Check and fill greasing in air ventilation fan and both bearings.

- Check earth connection with motor body foundation.

- Clean with air blower and clothe properly.

Parameters status :

After carried out maintenance activity we should check parameters for equipment better health.

- Incoming Voltage

- Check load according capacity.

- Check parameters according default limit.

- Check any abnormal sound.