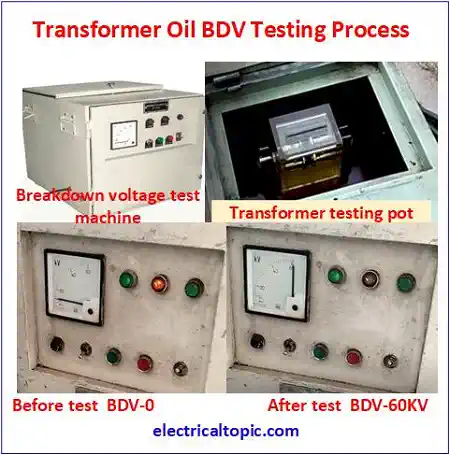

Transformer Oil BDV- Break Down voltage Test

Testing Kit and Testing procedure.

1- Transformer oil BDV- Breakdown voltage test:

Transformer BDV test is carried out to the transformer oil which is used for moisture or dielectric strength checking in transformer oil. Due to moisture,losses of transformer is increased as per permissible limit. For better transformer operation, oil insulation capacity should be good. The moisture is very harmful for transformer oil die electric strength.

Due to water content in oil, the die electric strength is decreased and insulation paper, winding insulation, oil insulation resistance capacity got decreased. So breakdown voltage test is so important for transformer health. After increasing losses in oil type transformer we should check breakdown test so that we can get availability of moisture content in transformer oil.

2- Testing kit or equipment of BDV test:

3- Test kit specifications for BDV test:

BDV test kit specification:

- Power supply : 230 V +/- 10% with 50 Hz frequency.

- Out put voltage range : 0 to 1000 KV AC

- Display panel: 3 1/2 digital panel meter.

- Control Switches:HT voltage ON and OFF, increased and decreased.

- HT voltage zero start facility for safety.

- Over voltage protection.

- Fast tripping during at dielectric breakdown.

- Push button for controlling.

4- Safety guidelines for BDV test:

Oil Breakdown voltage test is a high voltage test which is performed 0 to 100KV high voltage. Safety guideline should be used before test.

- BD test equipment should be connected with earth.

- During taking sample for testing, open the valve slowly and flush 2-3 times testing pot and then should fill the testing pot.

- During placing or removing the testing pot in BDV Instrument, The high voltage supply should be switched off.

- Testing pot should be kept in static mode as 5-10 minutes for removing air bubbles.

- 40 KV to 50 KV testing standing voltage is used for 11 KV HT system.

- 60 KV testing standing voltage is used for 33 KV HT system.

5-Transformer oil BDV test procedure:

A- 11KV transformer oil BDV test procedure:

- All safety guideline should be followed during testing procedure which is mentioned above.

- Put the testing pot on testing place.

- Start the on button of high voltage.

- start the increasing voltage 0 V to top side increasing condition as 2KV /Second.

- After reaching 40 KV or 50 KV then it should be continue stand on 1 minute.

1-Testing condition one:

If the testing pot electrode got fleshed before reaching the 40 KV or 50 KV or standing for 1 minutes then the die electric strength of transformer oil is low or moisture content is available in oil. It means the oil dehydration is required for removing moisture.

2-Testing condition two

If the testing pot electrode does not trip or high voltage stands as one minute required limit then transformer oil die electric strength is good and no moisture is available. It means no any oil dehydration is required.

B- 33KV transformer oil BDV test procedure:

- All safety guideline should be followed during testing procedure which is mentioned above.

- Put the transformer oil pot on testing place in testing machine.

- Start the on button of high voltage.

- start the increasing voltage 0 V to top side increasing condition as 2KV /Second.

- After reaching 60KV then it should be continue stand on 1 minute.

1-Testing condition one:

If the testing oil pot electrode got fleshed before reaching the 60 KV standing for 1 minutes then the die electric strength of transformer oil is low or moisture content is available in oil. It means the oil dehydration is required for removing moisture.

2-Testing condition two

If the testing pot electrode does not trip or high voltage stands as one minute required limit then transformer oil die electric strength is good and no moisture is available. It means no any oil dehydration is required.

6-BDV test observation according strandard parameters:

- If the break down test is failed before required parameters as per 11 KV or 33 KV HT system it means oil dehydration is required.

- If the breakdown tes is succeeded or passed as per 11 KV or 33 KV HT system it means oil dehydration is not required.