VFD- Variable frequency drive

Working principle, Diagram, Advantage and disadvantage.

1 - What is the VFD full form? :

VFD means variable frequency drive and it is used for energy saving through frequency controlling.

- Variable:-Electrical motor speed is controlled as per requirement so it is called variable.

- Frequency:Frequency means the flow of current so speed can be controlled throug frequency

- DriveDrive is a electrical machiene which is used for electrical to mechenical energy conservation.

2 - What is the VFD and why it is used? :

A- VFD:

Variable frequency drive is electronic device which is used for controlling the speed of AC induction motor. It has two main functions that one is speed controller and second is energy savings. Motor speed is controlled according frequency control which is controlled by VFD. It is mostly used in water pump motor, air blower motor, fans etc.

B- Why it is used

When induction motor is connected to the water pump or air blower then it moves 100 percent speed. if the water pump or blower load is low then motor moves as same as on load. Without VFD the motor takes current as same on load low or more.

For energy saving the VFD is connected for speed controlling as per load if the load is less then motor moves slowly so in this way we can say VFD is used for energy savings. VFD main functio below mentioned.

- Motor start and stop controlling.

- Motor speed control according load capacity.

- Air blower or AHU is controlled according temp.

- Water pump is controlled water pressure and water temp.

3 - Connection and wiring diagram of VFD :

4 - VFD Working principle :

VFD is an electrical frequency control device. It has two main important functions like as one is speed controlling and second is smooth start and stop of AC drive. These features of VFD makes a best controller of induction motors, blowers, fans et.

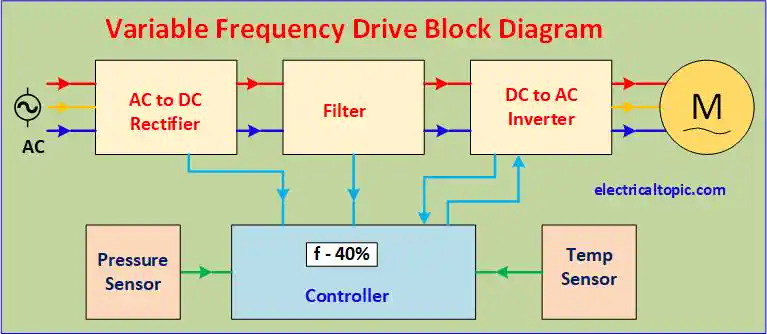

Working of VFD is the combination of four sections working. Without any section the VFD will not work so all four section is important for working.

- Rectifier Section

- Filter section

- Inverter section

- Controller section

1- Rectifier Section:

In this sections The diodes are used for AC to DC form through brig rectifier process. Here the 6 diode are used for power conversion like as three numbers diode are connected for positive and three others are connected as negative. Three phase R,Y and B are connected to across the diode. For getting output in sine wave form the diodes works in reverse and forwarding condition.

2- Filter Section:

We know very well that the output of rectifier is not a pure DC which is effected of AC ripples and harmonic rays. For getting pure DC the power capacitors are used which is connected with parallel to the rectifier output.

3- Invertor or Switching Section:

Invertor is a convertor which converts DC supply into AC supply. In this section many electronic components are used for converting AC to DC. Its works as apposite in comparison of diode. For this process many high power electronic switches are used like as IGBT or MOSFET.

These switches are operated as ON or Off rapidly and output is received as pulsating. For getting high frequency output, the switching device works as rapidly and for low frequency the switching device works as slow./P>

4- Controller:

Control unit is a microprocessor based electronic device which monitors and controls to the rectifier and invertor section. Some important features are below mentioned.

- Speed is controlled through speed sensor in auto mode.

- Speed is also controlled through user interface in manual mode.

- It provides necessary data.

- Any fault condition is also monitored and fault data is stored in history.

5 - Advantage of VFD :

VFD has more benefits not only energy savings but other benefits also.

1- Energy Savings:

The energy saving is the important benefits of VFD because equipment is operated according load requirement. Suppose a AC blower motor is operated according temp if the temp is high then blower will move normal RPM, If the temp is low then the blower will move slow . The speed of blower is controlled by VFD according temp.

Without VFD the blower is operated in normal speed through normal starter.

2- Improve of mechanical life:

Motor starts and stops in smoothly without any jerks so no any mechanical stress is available. The life of all mechanical parts is increase like as bearings, bush etc.

3- Low maintenance:

Due to smooth operation of blowers or motors, the life of mechanical parts, insulation of windings and cables are improved. The life of parts will increase then the maintenance of equipment will be decrease.

4- Protection:

The VFD also provides the protection against from overload, over voltage and phase loss. These such type any fault is available the VFD immediate stop the power supply.

5- Easy installation:

The VFD is the pre programmed form manufacturers so it is minimum wiring required. Due to minimum wiring, the process of installation is very easy.

6- Soft starter:

When motor starts then it takes a loat of current and stops with jerks. VFD also works as soft starter like as motor start and stop smoothly without any jerk or over current.

6 - Disadvantage of VFD :

1- Initial high cost:

VFD is a programmable digitally device so it initial cost is very in comparison of normal starter.

2- Maintenance high cost:

Maintenance cost of VFD is very high and parts cost is very high. It has required a expert engineer.

7 - Applications of VFD :

- It is used in AC chiller system for controlling the temp and smooth running.

- It is used in water pump system for controlling the water pressure ans smooth running..

- It is used in lift and escalator for start and stop smooth operation.

- Now a days the VFD is using as soft starter for smooth start and stop motors, blowers and fans etc.