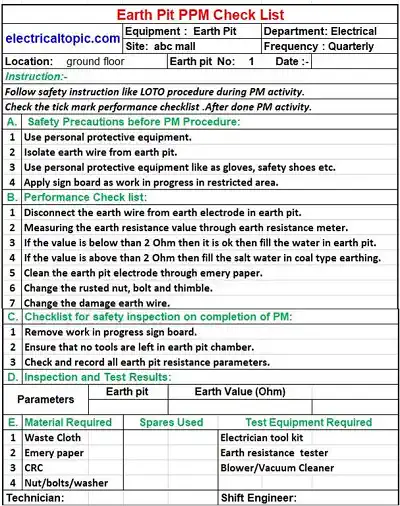

Earth Pit maintenace

Procedure and activity checklist.

1 - Earth pit Preventive Maintenance:

PPM is a planned preventive maintenance which is planned in annually basis activity schedule. Any equipment PPM schedule can be done according his nature and characteristic. This activity is done for maintaining health of equipment.

Here we are going to discuss about earth pit preventive maintenance so that health could be maintain. PPM schedule can be categorized in quarterly and yearly. The all parts of earth pit is checked in this schedule activity like as earth pit electrode, electrode connection, value of earth resistance.

2 - Earth pit maintenance checlist :

3 - Earth pit PPM Schedule :

- Quarterly PPM schedule.

- Yearly or Annually PPM Schedule.

4 - What is the Frequency of Earth Pit Maintenance or Schedule ?:

Earth pit PPM working procedure is carried out according time schedule. The procedure of PPM is going to explain according time schedule as per below mentioned.

1 - Quarterly PPM procedure:

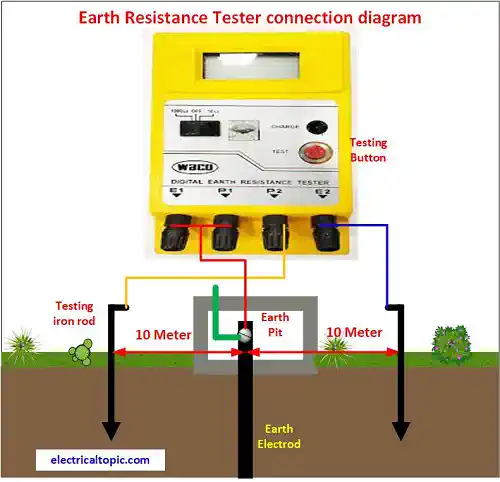

Quarterly ppm of earth pit is carried out after earth wire isolated form earth electrode and other safety precautions.

- Check earth pit resistance value it should not be below 2 ohm.

- If the resistance value is more then 2 ohm then fill the salt solution in earth pit.

- If the resistance value is below 2 ohm then fill the water in cole and salt type earthing pit through funnel for moisture increasing.

- Clean the rusted electrode terminal point with CRC and emery paper.

- Use grease on earth electrode terminal.

2 - Yearly or annually PPM procedure:

Annually ppm of earth pit is carried out after earth wire isolated form earth electrode and other safety precautions.

- Check earth pit resistance value it should not be below 2 ohm.

- If the resistance value is more then 2 ohm then fill the salt water in earth pit.

- If the resistance value is below 2 ohm then fill the water in cole and salt type earthing pit through funnel for moisture increasing.

- Clean the rusted electrode terminal point with CRC and emery paper.

- Use grease on earth electrode terminal.