Transformer Preventive Maintenance (PPM)

Activity Procedure according maintenace checklist.

1 - Transformer PPM- Planned preventive maintenance :

PPM is a planned preventive maintenance which is planned in annually basis activity schedule. Any equipment PPM schedule can be done according his nature and characteristic. This activity is done for maintaining health of equipment.

Here we are going to discuss about transformer preventive maintenance so that health could be maintain. PPM schedule can be categorized in daily, monthly, quarterly, half yearly and yearly. The parts of equipment is checked in this schedule activity like as breather, conservator, buchholze relay, terminal, on load tap changer, oil temp indicator, winding temp indicator and RTCC panel. Accept daily, for other schedule activity, a shut down of equipment will be require.

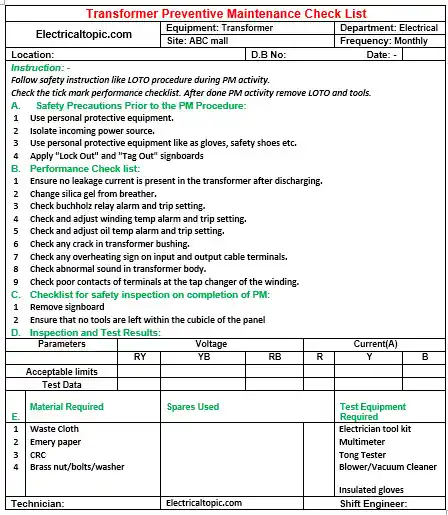

2 - Transformer PPM checklist template:

2 - Transformer PPM Schedule:

- Daily Check schedule

- Monthly PPM schedule.

- Quarterly PPM schedule:

- Half yearly PPM schedule:

- Yearly or Annually PPM Schedule:

3 - Transformer PPM Procedure :

PPM working procedure is carried out according time schedule. The procedure of PPM is going to explain according time schedule as per below mentioned.

1 - Daily inspection procedure:

Daily check is carried out as monitoring and visibly inspection type. If any problem is found out in daily check then action is taken.

- Oil leakage check around oil tank.

- Silica gel color check in breather

- Tank oil level check on the conservator.

- OLTC oil level check on the conservator where OLTC is inbuilt.

- Current oil temp check according blue needle in oil temp indicator instrument.

- Highest daily oil temp check according red needle in oil temp indicator instrument.

- Current winding temp check according blue needle in winding temp indicator instrument.

- Highest daily winding temp check according red needle in winding temp indicator instrument.

- Voltage and load in current check from HT panel multi function meter.

- Transformer tap nos check from remote tap changer controller.

- Check any abnormal sound.

2 - Monthly PPM procedure:

Monthly ppm of transformer is carried out after taking shut down and other safety precautions.

- Switch Off the power supply from HT panel and circuit breaker also should be rack out.

- Use lock out and tag out on the HT panel breaker

- Check the silica gel breather, if the color is pink then it should be change.

- Clean the drain pot of breather.

- Check the any hot spot in control circuit and thimble of motor in OLTC chamber.

- Clean the OLTC chamber with air blower.

- Check and tight all connection in OTI and WTI panel.

- Clean the OTI and WTI control panel with air blower.

- Check the buckholze relay visibly through glass.

- Daily check activity is also carried out with monthly schedule.

3 - Quarterly PPM procedure:

Quarterly ppm of transformer is carried out after taking shut down and other safety precautions.

- Switch Off the power supply from HT panel and circuit breaker also should be rack out.

- Use lock out and tag out on the HT panel breaker

- Monthly PPM schedule activity also carried out .

- Daily check activity is also carried out with monthly schedule.

4 - Yearly or annually PPM procedure:

Yearly ppm of transformer is carried out after taking shut down and other safety precautions.

- Switch Off the power supply from HT panel and circuit breaker also should be rack out.

- Use lock out and tag out on the HT panel breaker.

- The condition of transformer oil is checked through breakdown test according high voltage.

- Buchholze relay is checked and tested properly like as float valve, alarm and tripping contact.

- OTI and WTI relay is calibrated and tested.

- Oil dehydration process is carried out after oil breakdown test failure.

- OLTC taping chamber is clean properly.

- Oil level is maintained after oil dehydration.

- All protection relay is tested and calibrated according requirement.