Transformer Oil Dehydration

Working procedure and frequency.

1- Transformer Oil Dehydration Maintenance:

Oil dehydration is part of annual maintenance which is carried out due to moisture content is mixed in transformer oil with time resultant the losses of transformer increases. Losses of transformer is relate with energy consumption. If the losses will increase then energy loss also will increase.

So it is most important to reduce the losses of transformer. First of all we will have to use oil dehydration process for removing moisture from transformer oil. In this process, first oil breakdown test is carried out then oil dehydration process is processed.

2- Required Oil Dehydration Equipments:

- Fresh transformer oil for top up.

- Arrangement of required tool.

- Electrical cables

- Oil dehydration machine.

- Oil breakdown test instrument.

3- Safety Guidelines for Dehydration Procedure:

Transformer is electrical static equipment which is operated on high voltage. Any leakage of high voltage may be dangerous to maintenance manpower so it is so important to follow the safety guidelines which below mentioned.

- HT circuit breaker should be switched off and rack out.

- Lock out and tag out should be used on HT panel.

- Use floor guard for oil dropping on floor.

- The oil breakdown test should be carried out before and after during oil dehydration process.

- Cable size should be more against the ratings of oil dehydration machine.

- For using top up transformer oil should be top up after dehydration process.

4- Oil Dehydration Working Procedure:

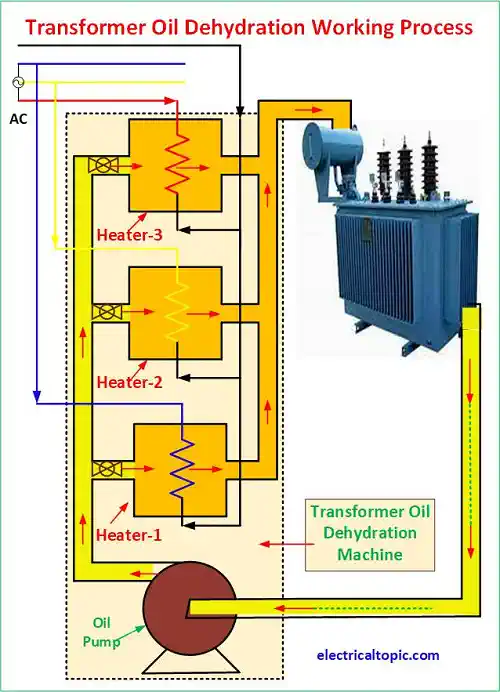

Oil dehydration is a moisture removing process from transformer oil. The process detail is below mentioned.

1- Initial Process:

- Switched off and rack out the incoming and outgoing circuit breaker.

- Use LOTO procedure on transformer incoming and outgoing panel.

- Connect to the dehydration machine to the electrical panel.

- Connect dehydration machine receiving oil pipe to the transformer drain pot.

- Connect dehydration machine discharging oil pipe to the conservator top up pot.

- Before start the process, measure the oil breakdown value and note down.

2- Dehydration process:

- Start the dehydration process and after going the four and five hours, the break down test should be carried out.

- Spare transformer oil should be also carried out dehydration process and should be top up in transformer.

3- Breakdown test:

- If the HT supply is 11 KV then break down value should be 50 KV and stand for one minute.

- If the HT supply is 33 KV then break down value should be 60 KV and stand for one minute.

- If the break down test is ok then dehydration process should be use one hour more.

4- Dehydration of OLTC Chamber:

- Drain out the oil from OLTC chamber so that OLTC chamber could be checked and clean properly.

- After cleaning and checking the oil dehydration process will be followed as per tank dehydration.

- Check oil breakdown test on OLTC chamber same as oil tank.

Other maintenance activity also carried out like as silica gel replacing, buchholz relay maintenance, OTI and WTI maintenance etc. After completing dehydration process, the transformer should be check load, sound or any leakage.