Equipment Health Checklist

Template, Types of Checklist and Checkpoints.

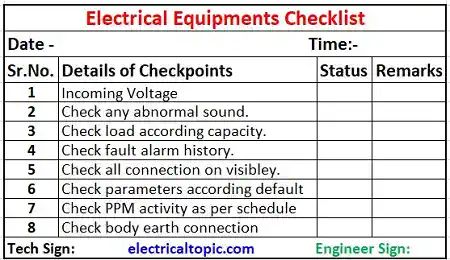

1- Equipment health checklist :

Equipment checklist is a formate of checkpoints which is used for equipment status checking. Checklist is used in daily basis or weekly basis. We can check any electrical or technical equipment properly according checkpoints like as abnormal sound, any heating, vibration, efficiency. leakage, filter condition, bearing play etc.

2- Checklist format or template:

3- Types of checklist:

Different type checklist are used according equipment characteristic. Different types checklist are available in electrical, mechanical, HVAC, WTP, BMS system. Types of checklist below mentioned.

- Health status checklist.

- Maintenance checklist.

- Parameters checklist.

- Testing checklist.

1- Health status checklist.

Health status checklist is used for knowing currently status of running equipment. Health status points below mentioned. running hours, over load or under load, abnormal sound, Vibration, Any fault status. filter condition etc.

- Check current load condition.

- Check abnormal sound.

- Check vibration.

- Check filter condition.

- Check any fault as currently and twenty four hours in history.

2- Maintenance checklist.

Maintenance checklist is used during maintenance period. Maintenance activity is carried out according checklist points like as below mentioned. LOTO procedure, tight loose connection,

- Use LOTO procedure.

- Check all connections and tight properly.

- Change any heat or faulty parts.

- Clean dust properly inside and outside.

- Remove any vibration.

- Check any abnormal sound.

3- Equipment parameters checklist.

Some electrical equipment parameters are very important for knowing its status.

- Input supply.

- Output supply.

- Load according capacity

- Temp and humidity.

4- Equipment testing checklist.

Equipment testing is carried out with time as after commissioning or yearly.

- Check default setting parameters.

- Use safety LOTO procedure during electrical high voltage equipment.

- Test default setting through test instrument.

- Calibrate equipment according default setting like as meters, pressure gauge.

- Connect the electrical testing Instrument with earth.

4- Types of equipment checklists:

- HT panel checklist.

- Transformer checklist.

- LT panel checklist.

- WTP plant checklist.

- Chiller plant checklist.

- DG checklist as A check, B check, C check and D check.

- AHU checklist.

- Starter panel checklist

- Capacitor panel checklist

- Production machine checklist.

- fir equipment checklist.

- Electrical equipment checklist

- Access control status checklist.

5- Why it is used?:

Check list is a important part for health of any equipment. Checklist activity is performed on daily basis, weekly or monthly basis. If checklist activity is carried out per day then we can know about equipment actual status. If any type problem is present in equipment then we can resolve or repair of problem. So in this way we can say checklist activity is carried out equipment health and performance.