Electrical Motor PPM Maintenance

Schedule, Procedure and checklist.

1 - Electrical motor planned Preventive Maintenance(PPM):

PPM is a planned preventive maintenance which is planned in annually basis activity schedule as weekly, monthly Quarterly, halfyealy and annually. Any equipment PPM schedule can be done according his nature and characteristic. This activity is done for maintaining health of equipment.

Here we are going to discuss about electrical motor preventive maintenance so that health could be maintain. PPM schedule can be categorized in daily, monthly, quarterly, half yearly and yearly. The parts of equipment is checked in this schedule activity like as cooling fan, both side bearings, foundation vibration, coupling, earth connection, terminal connection etc. Accept daily, for other schedule activity, a shut down of equipment will be require.

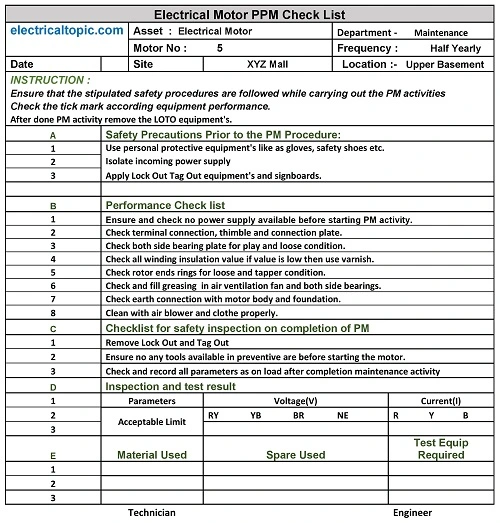

2 - Electrical motor PPM checklist template :

3 - Electrical motor PPM Schedule :

- Weekly PPM schedule.

- Monthly PPM schedule.

- Quarterly PPM schedule.

- Half yearly PPM schedule.

- Yearly or Annually PPM Schedule.

4 - Electrical motor PPM Procedure :

PPM working procedure is carried out according time schedule. The procedure of PPM is going to explain according time schedule as per below mentioned.

1 - Weekly PPM procedure:

Weekly PPM is carried out as monitoring and visibly inspection type. If any problem is found out in weekly check then action is taken for rectifying the problem.

- Check input voltage according default voltage.

- Check total load performance according rating capacity.

- Clean the motor with air blower and clothe.

- Check abnormal sound during running on load.

- Check vibration in foundation and coupling.

- Check motor heating on running load.

- Check cooling fan sound, vibration and function.

- Check connection in motor terminal.

2 - Monthly PPM procedure:

Monthly ppm of electrical motor is carried out after power supply source isolated from starter panel and other safety precautions.

- Switch Off the power supply from motor starter panel.

- Use lock out and tag out on the motor starter panel.

- Weekly PPM activity is also carried out with monthly schedule.

- Check and tight loose connection on motor terminal.

- Change any heat thimble in motor terminal plate.

- Tight foundation nut and bolt properly.

- Check alinement of motor and pump.

- Check and tight earth connection with motor body.

- If the foundation rusted condition then painted it.

3 - Quarterly PPM procedure:

Quarterly ppm of electrical motor is carried out after power supply source isolated from starter panel and other safety precautions.

- Switch Off the power supply from motor starter panel.

- Use lock out and tag out on the motor starter panel.

- Weekly PPM activity is also carried out with monthly schedule.

- Monthly PPM activity is also carried out with quarterly schedule.

3 - Half yearly PPM procedure:

Half yearly ppm of electrical motor is carried out after power supply source isolated from starter panel and other safety precautions.

- Switch Off the power supply from motor starter panel.

- Use lock out and tag out on the motor starter panel.

- Weekly PPM activity is also carried out with monthly schedule.

- Monthly PPM activity is also carried out with half yearly schedule.

4 - Yearly or annually PPM procedure:

Monthly ppm of electrical motor is carried out after power supply source isolated from starter panel and other safety precautions.

- Switch Off the power supply from motor starter panel.

- Use lock out and tag out on the motor starter panel.

- Fill the grease both side bearings.

- If the bearing play then replace it.

- Cooling fan shaft play then bearing or bush change.

- Check motor winding insulation if the insulation weak than spread the vanish on windings.

- Check the motor body and foundation rusted condition if rusted then painted it.