OLTC- On Load Tap Changer transformer

Types, Parts, Working Procedure.

1- On Load Tap Changer Transformer:

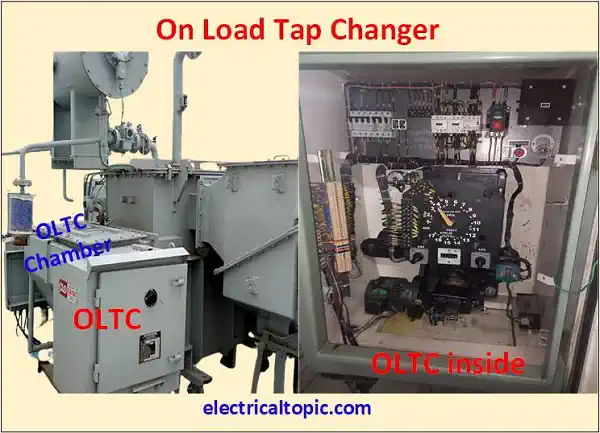

OLTC stands for On Load Tap Changer, means voltage is regulated in transformer in running condition. It is installed in a separate chamber and connected with primary winding. It is used in oil type transformer with 17 no’s taping.

2- Parts of OLTC :

1. Tap changer tank.

Oil chamber is used for installation of tap changing mechanism. Oil is used for arc quenching during tap changing process. Transformer oil works as insulation and cooling for tap changing mechanism.

2. Tap changing mechanism.

This mechanism is installed in OLTC oil chamber. Moving and fixed contact are mounted on it. Fixed taping contacts are connected with primary winding. Primary winding is distributed in 17 nos of taping points. Moving contact is mounted on drum type roller. Roller can be moved by auto and manual.

3. Motor drive mechanism.

It is installed outside with oil chamber. Tap changing roller shaft is comes out in drive box. The gears are connected with this shaft for using motor and tap counter and handle.

4. Motor/tap control unit.

Motor is connected with tap changing rolling shaft with the help of gears. A tap counter is also connected with the help of gear. The rolling shaft can be moved by motor with the help of control circuit as motor moving reversing and forwarding. The drive can be moved by manually with handle in the condition of motor malfunctioning.

5. Protection Unit.

Silica gel breather and Buchholz relay is used for protection of OLTC. The Buchholz protection relay is installed between conservator and oil chamber tank. If any incident inside the tank the Buchholz relay will be activate. Silica gel breather is used for preventing from moisture in oil.

3- Working principle of OLTC in transformer :

1- Tap changing by Push button of control circuit.

tap changing shaft can be moved by control circuit which is moved reversing and forwarding by motor. If we want to increase the voltage than select the selector switch in forward mode and press the push button for getting required voltage. If we want to decrease the voltage, we will have to select the selector switch in reverse mod and press the push button. Motor drive will move reverse and forwarding by pressing push button.

2- Tap changing by handle.

During motor out of order the handle can be used for moving shaft of tap changing drive. First, we will have to fixed the handle on drive shaft after that we will have move handle forward side or backward side. tap changing counter also move and will show the condition of tap changing.

4- Technical Specification of OLTC:

| Sr.No. | Parameters | Value |

|---|---|---|

| 1 | Voltage ratings: | 11 KV to 33 kV |

| 2 | Tap position | 17 Nos |

| 3 | Step voltage | Max 300 volt for 11 KV 412 volts for 33 KV. |

| 4 | Motor voltage | 415 volt |

| 5 | Control voltage | 110 volt |