Transformer Winding Temp Indicator(WTI)relayWorking principle, Connection diagram.

1- Transformer winding temprature indicator(WTI):

Winding is the important parts of transformer which is costly part so for winding safety, the winding temp indictor relay is used for protection. A more current increases due to over load and short circuit then the winding temp also increases. Due to high temp, the winding may be failure or oil tank may be damage. During load condition the current is circulated through winding then winding temp increases.

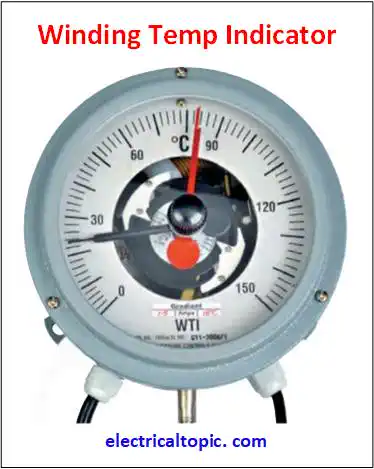

2- Construction of WTI:

According above figure the black needle shows to the current temp and red needle shows the highest temp of the day. After 24 hrs the red needle is reset manually.

The green and red, two knobs are used for temp setting. The green knob is used for alarm temp setting and red knob is used for temp trip setting.

Bushing current transformer is installed on tank for receiving temp in resistance.

3- WTI gauge relay temp setting:

The main purpose of WTI is to indicate the winding temp of transformer high voltage and low voltage windings. default temp setting of WTI is 80 and 85 degree centigrade. Fist alarm setting is 80 degree centigrade and 2nd tripping setting is 85 degree centigrade.

- Alarm setting:80 degree centigrade

- Trip setting:85 degree centigrade

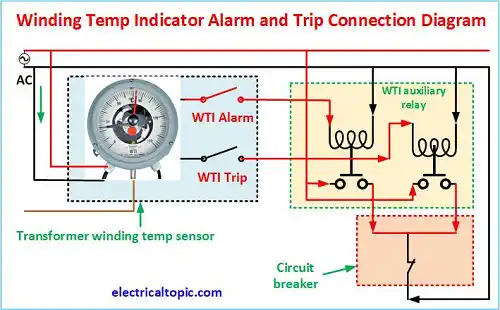

4- Connection diagram:

5- Working principle:

A indirect temp system is used for measuring the winding temp. Due to high voltage any sensor ot temp can not be close with windings. so thermal temp sensor is used through current transformer

A liquid is filled in measuring equipment and heating resistance is connected to the bushing current transformer. It is proportional to the winding temp. When winding temp is rises then heating resistance temp also increases resultant the instrument volume is increase and needle moves.

WTI instrument liquid volume is increase according default setting if the temp in 80 degree centigrade then alarm contact will be closed resultant hooter will be activate on HT panel. If the temp is 85 degree centigrade then the trip contact will be close resultant HT panel circuit breaker will be tripped.

6 - Why winding temp indicator(WTI) is used?

Oil Transformer is a costly equipment. Due to over heating, overload or short circuit in the oil tank,

resultant winding insulation may be failure or explosion in oil tank. So prevention for winding and explosion

in tank, The WTI relay is

installed on the middle of body.

When a fault is occurred in a tank or over load condition then major current is circulated in winding

resultant a more temp is produced in windings. This winding temp is proportionals to the WTI temp sensor.

instrument is activated and a signal

of alarm and tripping is sent to the transformer incomer breaker. So in this way the oil transformer can be

prevented

by WTI.

Winding temp indicator has two important features which is mentioned in below.

- Due to any fault or overload condition in transformer windings then it provides alarm signal for protection on the HT panel.

- Due to any fault or overload condition in transformer windings then it provides trip signal for protection on the HT panel.