Oil Type Transformer

Parts and Their functions.

1 - What is the Oil Type Transformers?:

The oil type transformer is a famous electrical equipment for us it is also used in a bulk above 500 KVA. It is used as an outdoor or open area and oil is used in this. The transformer oil is also called as insulation oil. The efficiency of it is very good in comparison to others.

The function of oil is two types, one is arc quenching in tank and reduces the winding temp It is used as a cooling medium for winding and core during load and its dielectric strength is very good.

Different type categories of transformer are available as per requirements of industries or consumer. Everyone can see easily anywhere so we are going to discuss about oil type transformer. it is low cost against dry type transformer.

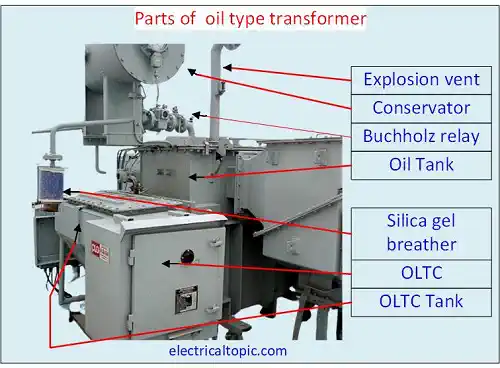

2 - Parts of oil type transformer:

1 - Tank:

Tank is a main body part of transformer. Both winding is kept in tank and oil is filled in it for cooling of winding. It is also used as base for installing other accessories on this tank body just like as terminal, bushing, conservator, breather vent pipe diagrammed, remote tap changer, Buchholze relay etc.

2 - Iron core:

Laminated iron core is used in transformer. It is work as base for installing winding. Transformer has two

nos winding one is primary and secondary. Both winding is installed on core. They are separately to each other

by limb. It has two no’s windows and two no’s limbs.

Iron core has two works.

- Base for installing winding.

- When presence of AC voltage in primary winding then generate magnetic flux and transfer to secondary coil.

Type of core:

- Core type

- Shell type

- Berry type

3 - Windings:

If we talk about what is the winding that answer will be it is the group of turns aluminum or coper conductor

as per conductor size and length of turns.

Transformer has two no’s winding.one is primary and other is

secondary.

- Primary winding: It is used for input side and AC power supply is applied on it.

- Secondary winding: it is installed at output side and output voltage is received from it.

4 - Transformer oil:

Transformer oil is known as insulated oil. It is used for heat removing from core and windings at high temp and any arching in tank. Between conductor it works as insulator. it has excellent dielectric strengthen. It has high flash point and thermal stability. It comes in market as two types.

- Paraffinic oil

- Naphthenic oil: is used in mostly because it has good dielectric strength in high temperature stability. The boiling point of this oil is 425°c.

5 - Terminal and bushing:

Terminal and bushing are installed on transformer for connecting power supply cable to input side and output side.

- Terminal: it is used for connecting the Power supply with winding. Two types terminal are used as input and output terminal. Terminal are mounted upon bushing.

- Bushing: It is installed on tank as insulator on tank and terminal. It is made by porcelain or

epoxy resin or ebonite.it is installed over tank.

- High voltage bushing: It is used in primary side as 11 KV and 33 KV voltage.

- Low voltage bushing: It is used in outside low voltage supply like as 433 voltages.

6 - Tap changer:

Tap changer is used in transformer for voltage regulating. It is connected at primary side winding. The primary side winding is distributed 17 no’s taping. Every taping is connected with tap changing. Two types tap changer are used in transformer ass on load tap changer and off-load tap changer.

Onload tap controller (OLTC):

OLTC stands for On line tap changer. it is a part of transformer which is used in buildings & industries. OLTC is used for 11KV and 33 KV voltage regulation. 415 standard voltages can be regulated for smooth operation of equipment’s like lifts / UPS / AHUs / Chillers & other many equipment’s.

7 - Explosion Vent:

It is known as safety device for protection to the oil type transformer. It is a vent pipe diaphragm which is made by aluminum. On upper end a thin mesh is provided so that during heavy fault in tank than it will be break. It works against internal fault and fumes and smoke generate into a lot of amounts. We can say it another name pressure relief vent during a heavy fault. it is installed above tank.

8 - Buchholze relay:

The Buchholz relay is used in transformer for protection. It is known as another name is gas Relay. It is installed

middle of tank and conservator.

It protects to the transformer as two types.

- Major fault occurred in transformer tank and generating gas in tank than it will provide alarm and trip protection.

- Oil level going to down than it will provide protection alarm and trip condition.

9 - Conservator:

It is a cylindrical tank which is mounted on transformer tank. It is the main work of conservator to manage the oil expansion. When temp increase of oil in tank than volume of oil level also will increase. This type condition the conservator will work as extra space for managing expending tank oil.

This increasing oil up moves upside to the conservator than oil will store in conservator tank. After decrease the temp of oil tank than oil will move to down side of conservator and fresh air will entered through breather.

10 - Silica gel breather:

Breather is installed on conservator for removing moisture and dust particle from entering air through breather. Breather is used in transformer for breathing air in and out in body of transformer during thermal expansion of oil.

During the time of operating when is loaded by power. Same time the ambient temp of out is also more than tank oil temp will increase and oil label also will be increased. Due to oil label increasing the tank oil will move towards conservator side than conservator air will move outside through silica gel of breather.

When unloaded or decrease the label of tank oil than conservator oil will move to downside than conservator will suck air through silica gel breather. This process is called transformer breathing.

Silica gel function:

It is used inside of breather bottle when the air enters in the breather through silica gel than moisture and dust will be absorb by silica gel. After absorbing the air moisture, the silica gel color will be changed blue to pink. This type silica gel should be changed ass on urgent basis.

Color off Silica gel:

- Dark blue: Dry type silica gel.

- Light blue: Dry type silica gel.

- Pink color: 100% silica gel moisturized- Should be changed on urgent basis.

11 - OTI and WTI:

temp indicator is used for measuring the temp of transformer winding. If the temp of winding is crossed the permissible limit due to any fault like as short circuit, loss of insulation, then alarm and trip circuit will be activated. Resultant the breaker will be tripped by winding temp indicator (WTI) device.

Alarm and tripping limit of WTI can be set as per site requirements. The standard limit is below mentioned.

- Winding temp alarm: 80℃

- Winding temp tripping alarm: 85℃

Oil temp indicator

Oil temp indicator is used for measuring the temp of transformer oil tank oil. If the temp of oil in main tank is crossed the permissible limit due to any fault like as short circuit, loss of insulation, then alarm and trip circuit will be activated. Resultant the breaker will be tripped by oil temp indicator (OTI) device.

Alarm and tripping limit of OTI can be set as per site requirements.

The standard limit is below

mentioned.

- Oil temp alarm: 70℃

- Oil temp tripping alarm: 75℃