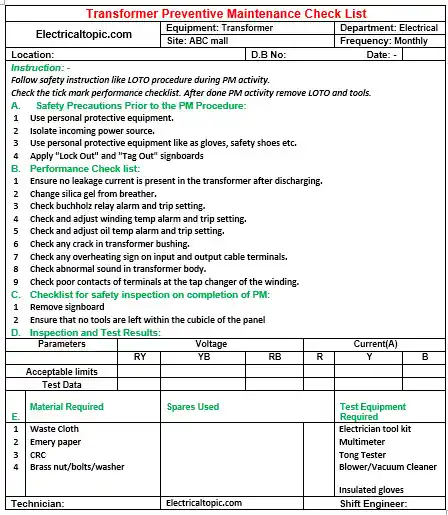

Transformer preventive Maintenance Checklist

Description, activity procedure and checkpoints.

1- Transformer preventive maintenance checklist:

Transformer is a costly electrical static device which is used for voltage transformation als low to high and

high to low. Preventive maintenance is a important activity for keeping healthy of transformer. Many type

maintenance activity is carried out as monthly, quarterly, half yearly and yearly.

These all activities

is

carried out according maintenance checklist which is written step by step maintenance process.

2-Format or template of Transformer PPM checklist:

- Ensure no leakage current is present in the transformer after discharging.

- Change silica gel from breather.

- Check buchholz relay alarm and trip setting.

- Check buchholz relay alarm and trip setting.

- Check and adjust winding temp alarm and trip setting.

- Check and adjust oil temp alarm and trip setting.

- Check and adjust oil temp alarm and trip setting.

- Check any crack in transformer bushing.

- Check any overheating sign on input and output cable terminals.

- Check abnormal sound in transformer body.

- Check poor contacts of terminals at the tap changer of the winding.

Parameters status :

After carried out maintenance activity we should check parameters for equipment better health.

- Incoming Voltage

- Check load according capacity.

- Check parameters according default limit.

- Check any abnormal sound.